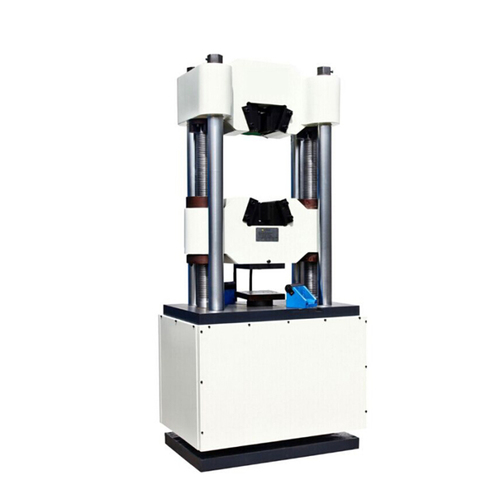

Universal Hydraulic Compression Testing Machine

Product Details:

Universal Hydraulic Compression Testing Machine Price And Quantity

- 10500 USD ($)/Unit

- 1 Unit

Universal Hydraulic Compression Testing Machine Trade Information

- SHENZHEN

- 15 Unit Per Week

- 5 Days

- Each set protected with resin fiber and PP film, then put into Strong wooden case with operation manual and video inside. CE,ISO

- Australia North America Eastern Europe Middle East Africa Central America South America Western Europe Asia

- Each set protected with resin fiber and PP film, then put into Strong wooden case with operation manual and video inside. CE,ISO

Product Description

universal hydraulic compression testing machineProduct Description

Structure introduction

universal hydraulic compression testing machine is mainly used to execute the tension, compression, bending, shearing etc. test for metal materials. Attached simple accessories and devices, it can be used to achieve many kinds of mechanical performances.

The oil cylinder is at the bottom of the load frame, tension space is at the upside of the load frame, compression and bending space is between lower cross head and working table. The lower cross head is driven by motor through decelerator, chain transmission device and screw pair, so realize the adjustment of testing space.

The universal hydraulic compression testing machine adopts oil pressure transducer to measure load, use computer control display load,

Main specifications hydraulic compression Test Machine

| Max. Test load: | 300KN |

| Load range: | 6KN-300KN |

| Relative error of indicate value of load : | 1% |

| Max. Ram stroke: | 250mm |

| Max. Tensile space: | 800mm(including piston stroke) |

| Max. Compression space: | 700mm(including piston stroke) |

| Display: | Computer control and display |

| Tensile grips for round specimen : | 6-26mm |

| Tensile grips for flat specimen: | 0-15mm |

| Distance for two columns: | 500mm |

| Upper and lower platen size: | 200x200mm |

| The span of bending: | 450mm |

| Width of bending roller: | 140mm |

| Dia. of bending roller: | 30mm |

| Clamping mode: | Hydraulically |

| Transducer: | load cell |

| Deformation measuring: | YYU10150 |

| Dimensions of load frame : | 990 x 600 x 2435mm |

| Dimension of controller : | 1140x700x930mm |

| All weight: | 2800kg |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Tensile Testing Equipment' category

|

HAIDA INTERNATIONAL EQUIPMENT CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese